Fasteners

High-strength bolts (hot-dip galvanized) are used, which can adapt to the harsh operating environment and are the ideal cooling tower building materials to resist changes in environmental conditions, as well as resist aging caused by ultraviolet rays and have strong corrosion resistance, ensuring the comprehensive service life of the equipment.

Spraying pump

special pump with high flow and low head

Shower system refers to the spray pump from the bottom of the tank suction water to the upper cooling tower spray pipeline, through the nozzle sprinkler, spray water evenly sprinkled to the cooling coil, cooling system, it belongs to the external cycle.

Spray pump: the use of closed cooling tower special water pump, its flow rate, low head, high efficiency, low noise, low power, evaporative condenser special water pump, the implementation of the standard according to JIS-C4210 implementation. Water pump motor voltage 380V, protection grade IP55, insulation grade F, explosion-proof motor. Meanwhile, it is equipped with advanced spraying water distributor, connected with ABS flower basket nozzle to form a uniform water film and achieve the best water vapor ratio. (The spray pump adopts the closed tower special pump of Boliyuan pump industry, the pump head is only 7m, compared with the original spray pump using 10m head: avoid the pump due to high head, but the closed cooling tower itself is low height and the pump overflow resulting in motor burnout phenomenon. More stable performance, longer service life)

Water distribution nozzle

The use of gravity natural pool type water distribution, with pool level, smooth orifice, water depth of 200mm, the advantage is to prevent blockage, water distribution uniform.

The use of 304 stainless steel floating ball valve, durable, not easy to corrode, prolonging the service life of the cooling tower.

The tower is equipped with a rotating and flexible maintenance door, and a spacious and safe maintenance walkway inside the tower.

Outside the tower can be equipped with 304 stainless steel climbing ladder guardrail, which is convenient for maintenance and overhaul of the fan and the upper part of the cooling tower.

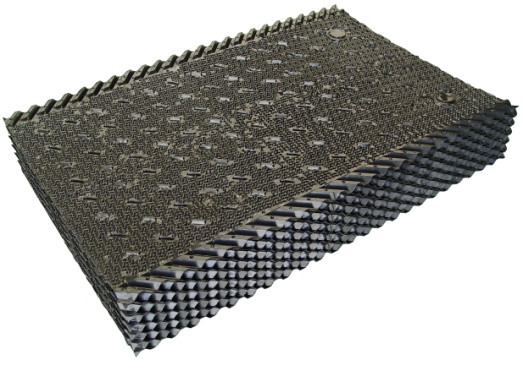

Filler

a. An important component of the closed cooling tower PVC heat exchange layer more effectively use the evaporative heat exchange of water to reduce the temperature of the water, and improve the efficiency of heat exchange.

b. The PVC heat exchange layer produced by our company is made by fully automatic computer-controlled high-speed blister molding machine, which enables the PVC heat exchange layer to be formed better and faster, and at the same time can ensure the overall consistency of the PVC heat exchange layer, so that it can give full play to a higher heat exchange rate.

C. Due to the special patented design, the surface presents rough, smooth plane, good hydrophilicity, absorption rate less than 0.015%, so that more water forms a film without splashing down, the water baffle in front of the PVC heat exchange layer effectively reduces the loss of floating water, so that the rate of floating water is less than 0.001%, which effectively saves water, and is especially suitable for areas where water resources are tight.